Hielscher Ultrasonics – Industrial Ultrasonic Devices

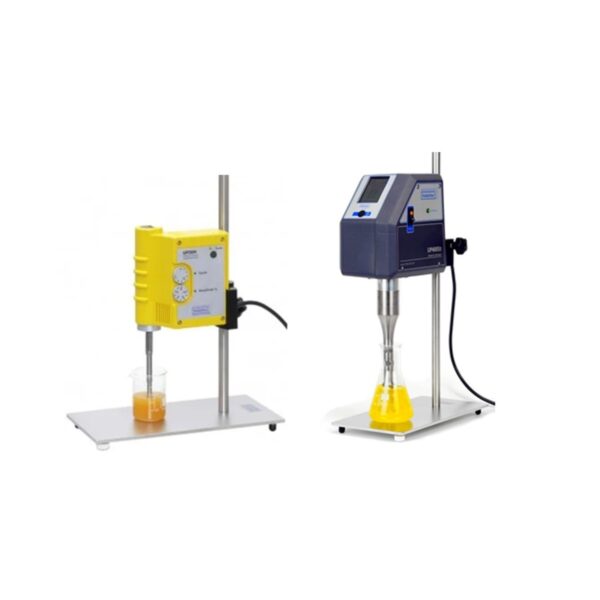

Hielscher industrial ultrasonic devices are powerful, efficient and reliable. They are built to operate continuously at high load in industrial environments. With up to 16kW per device, Hielscher is the leading ultrasonics supplier for industrial …

Hielscher industrial ultrasonic devices are powerful, efficient and reliable. They are built to operate continuously at high load in industrial environments. With up to 16kW per device, Hielscher is the leading ultrasonics supplier for industrial liquid processes.