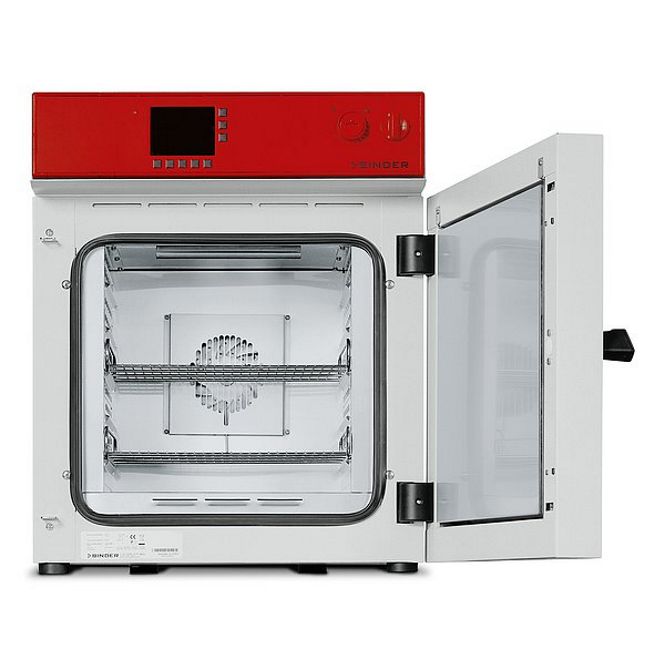

Binder – Drying and Heating Chambers – Series M – With Forced Convection and Advanced Program Functions

With a maximum of 300 °C and various programming options the M series material test chambers are ideal for material and aging tests. With a high air flow, the powerful fans ensure rapid heating.

Heating Chambers With Forced Convection and Advanced Program Functions

BINDER heating chambers in the Classic.Line M series are equipped with advanced program functions, allowing the units to be used in a wide range of applications. Whatever they are being used for, they never fall to impress with their high precision and performance. The drying and heating chambers with forced convection are ideally suited for the drying and heat treatment of solid or powdered chamber loads and bulk material with the introduction of heat. They also come highly recommended for drying processes and any tasks within the field of material and aging testing.

Heating Chambers With Forced Convection for High Performance and Ease of Use

Heating chambers in the M series feature an extremely powerful throughput of air and a programmable exhaust air flap that speeds up the heating up time. Testing temperatures can be maintained with precision at every level and are subject to only minimal spatial fluctuations. It is the patented APT.line™ preheating chamber technology together with the direct and streamlined air flow in the interior that guarantee the high levels of temperature accuracy in terms of space and time. These heating chambers operate within a temperature range of between 5 °C and 300 °C, with the temperature being displayed digitally to the accuracy of a tenth of a degree, and the fan speed can be adjusted on an individual basis.

BINDER heating chambers in the M series come in different sizes, and a range of optional accessories is also available. Their high performance levels are teamed with incredible ease of handling – all of the unit’s functions are clearly arranged and user-friendly. The simplicity with which all of the parts in the heating chambers can be cleaned is another definite plus that reduces the risk of undesirable contamination to a minimum.

Key Features

- Uniform drying conditions thanks to APT.line™ technology

- Identical test conditions throughout the chamber interior independent of sample size and quantity

- Outstanding thermal insulation saves operation costs

- Advanced programming options

Technical Specifications

| Model | Housing dimensions not incl. fittings and connections W x H x D | Internal dimension W x H x D | Net weight | Interior volume |

| M 53 | 635 x 780 x 575 mm | 400 x 400 x 340 mm | 61 kg | 53 L |

| M 115 | 835 x 865 x 645 mm | 600 x 480 x 410 mm | 89 kg | 115 L |

| M 240 | 1035 x 985 x 745 mm | 800 x 600 x 510 mm | 131 kg | 240 L |

| M 400 | 1235 x 1190 x 795 mm | 1000 x 800 x 510 mm | 173 kg | 400 L |

| M 720 | 1235 x 1690 x 865 mm | 1000 x 1200 x 610 mm | 203 kg | 720 L |

Available Models

Multi Management Software APT-COM™

Binder From the Inside – See What Happens Behind the Scene

Key Industries

- Education & Academics

- Food & Beverage

- Pharmaceutical

- Service

More Products

With 22,000 series production machines supplied each year globally, family company BINDER is now one of the leading experts on…